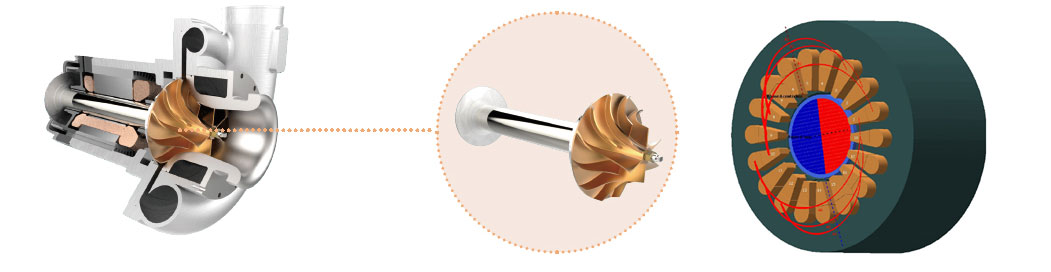

Direct driven Shaft

With one body rotor-impeller connection, the transfer of energy is simplified to minimize the loss of energy.

By use of air bearing that does not need oil lubrication, no periodic maintenance is needed.

With one body rotor-impeller connection, the transfer of energy is simplified to minimize the loss of energy.

By use of air bearing that does not need oil lubrication, no periodic maintenance is needed.

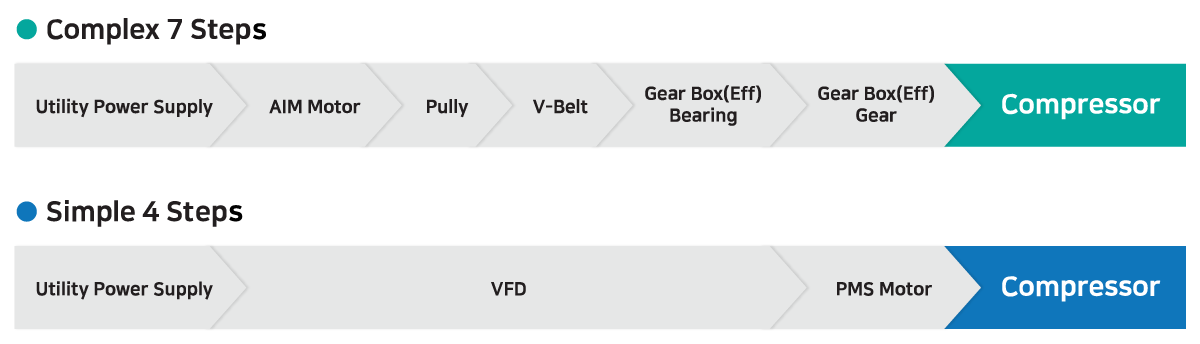

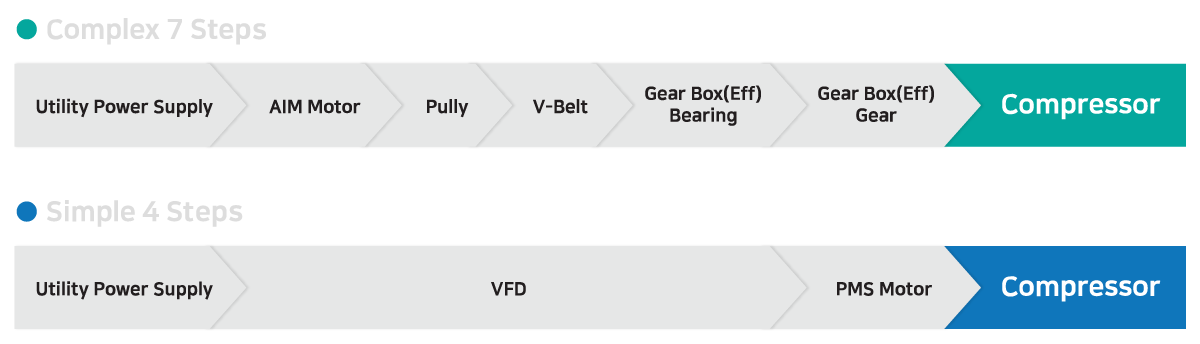

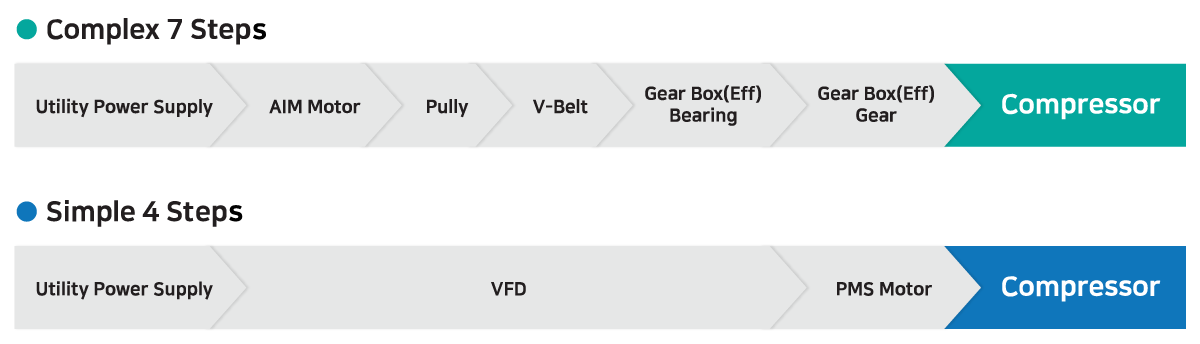

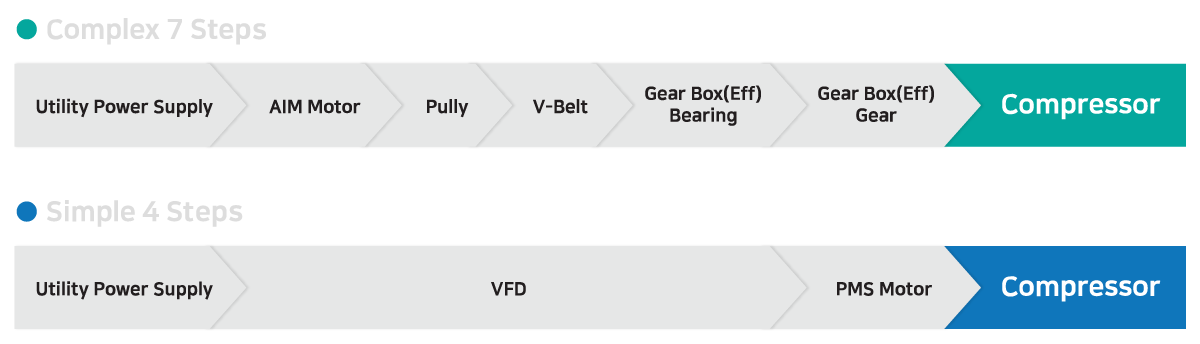

Permanent Magnet Synchronous Motor (PMSM) is proven the most efficient motor.

The physical size of the motor frame can be kept much smaller than ordinary induction motor at high power.

Accurate speed control is possible, so suitable for the turbo blower controlling flow by RPM control.

Direct connection with impeller means zero power transmission loss

[특허 제 10-0675821호]

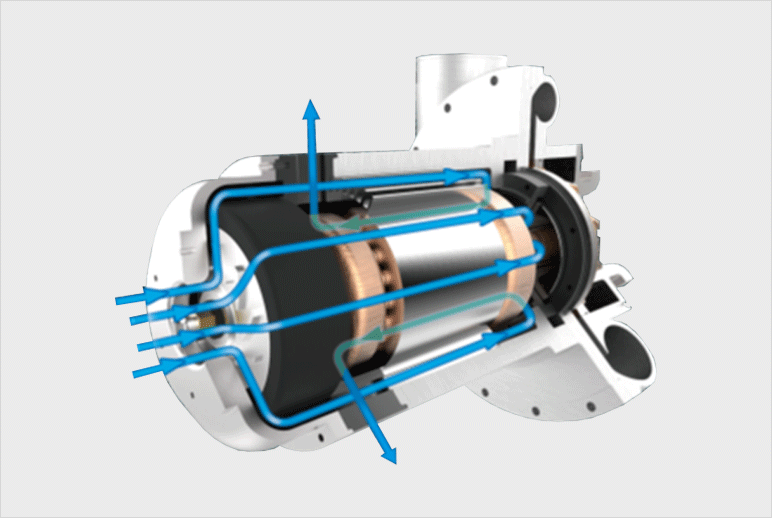

High-speed motors for turbo machines are small in size but produce great power.

Therefore, it is necessary to apply the cooling method best suited for your machines capacity and usage.

Keeping the motor coll will greatly affect the motor output and longevity.

For effective motor cooling, the heating sink area through the cooling pin inside was maximized.

The cooling efficiency was maximized by configuring an optimal flow path so that cooling air could circulate smoothly through the motor.

In the case of induction motors, if the load is lowered, the efficiency will also decrease.

In most wastewater treatment plants, air demand varies depending on the season or the amount of inlet wastewater, and the load rate of the motor varies.

PMSM is advantageous for energy saving because it maintains high efficiency over the overall load range.

Turbo blower has no loss of efficiency over time because there is no contact or frictional wear and tear.

On the other hand, ordinary PD blower efficiency deteriorates over time due to wear and tear and air leakage in the compressor.

However, the air bearing turbo blower does not require bearing replacement or periodic maintenance.

Headquarters : 208, Osongsaengmyeong 9-ro, Osong-eup, Heungdeok-gu, Cheongju-si, Chungcheongbuk-do, Republic of Korea

Hyeondo Factory : 12-21, Jugamdowon-ro, Hyeondo-myeon, Seowon-gu, Cheongju-si, Chungcheongbuk-do, Republic of Korea

TEㅣ : +8243-275-6002, FAX : +8243-275-6004